THE BIRTH OF FREITAG

In 1993 two graphic designers, Markus and Daniel Freitag, were looking for a robust, functional and water-repellent bag to hold their work. Inspired by the multicolored heavy traffic that trundled past their apartment every day on a major Zurich transit route, they developed a messenger bag from used truck tarps, discarded bicycle inner tubes and car seat belts. This is how the first FREITAG bags – each recycled, each unique – took shape in their living room.

FROM TRUCK TILL BAG

a.k.a the production of Freitag bags

STEP 1: TRUCKSPOTTING

The recycling of used truck tarps into unique, highly functional bags takes place in five highly complex steps at the factory.

It may not be Glencore. But sourcing the raw materials FREITAG needs is still pretty hard-core.

To ensure that our 250 F-Workers always have something to do and to eat, our five tarp buyers – also known as truck spotters – have to find and bring back approximately 500 tons of tarps to Nœrd a year.

Achieving this calls for them to be on the phone non-stop or prowl around the truck stops of Europe ...

… hunting down the best tarps in the hottest colors from trucks, truckers and haulage companies.

Once they arrive at the factory, the tarpaulins are given an ID for traceability and their constituents tested so that we can guarantee the safety of our products.

STEP 2: CUTTING UP THE TARPS

We need men like Thomas to turn the gigantic tarp monsters into one-off bags and accessories.

Their first job is to relieve them of eyelets, straps, belts and everything else a FREITAG bag doesn’t need..

With sharp eyes and even sharper knives, the toughest boys on the F-Crew recognize the potential of every tarp that lands on their two tables. They then hack and carve prime cuts from the scruffy beasts …

.... and cut them into standard 2.5-meter lengths, fold them and send them to the warehouse.

STEP 3: WASHING

What happens in the basement at the Nœrd has nothing in common with what you do in your laundry room – even though it might look almost the same

Obviously, bags have to be clean.

However, for our tarp washers like Mustapha and Zija, the real work is transforming “used” into “patina” and “old” into “vintage”. To achieve this, they use around 15,000 liters – almost 4000 gallons – of rainwater daily along with our secret tarp-wash bath additive.

After they’ve revealed the inner beauty of the tarps, and as soon as they are dry again ...

... the sheets are bundled according to color and sent to the bag designers.

STEP 4: BAG DESIGN

The bag designers ensure that our one-of-a-kind products are not just unique but uniquely beautiful as well.

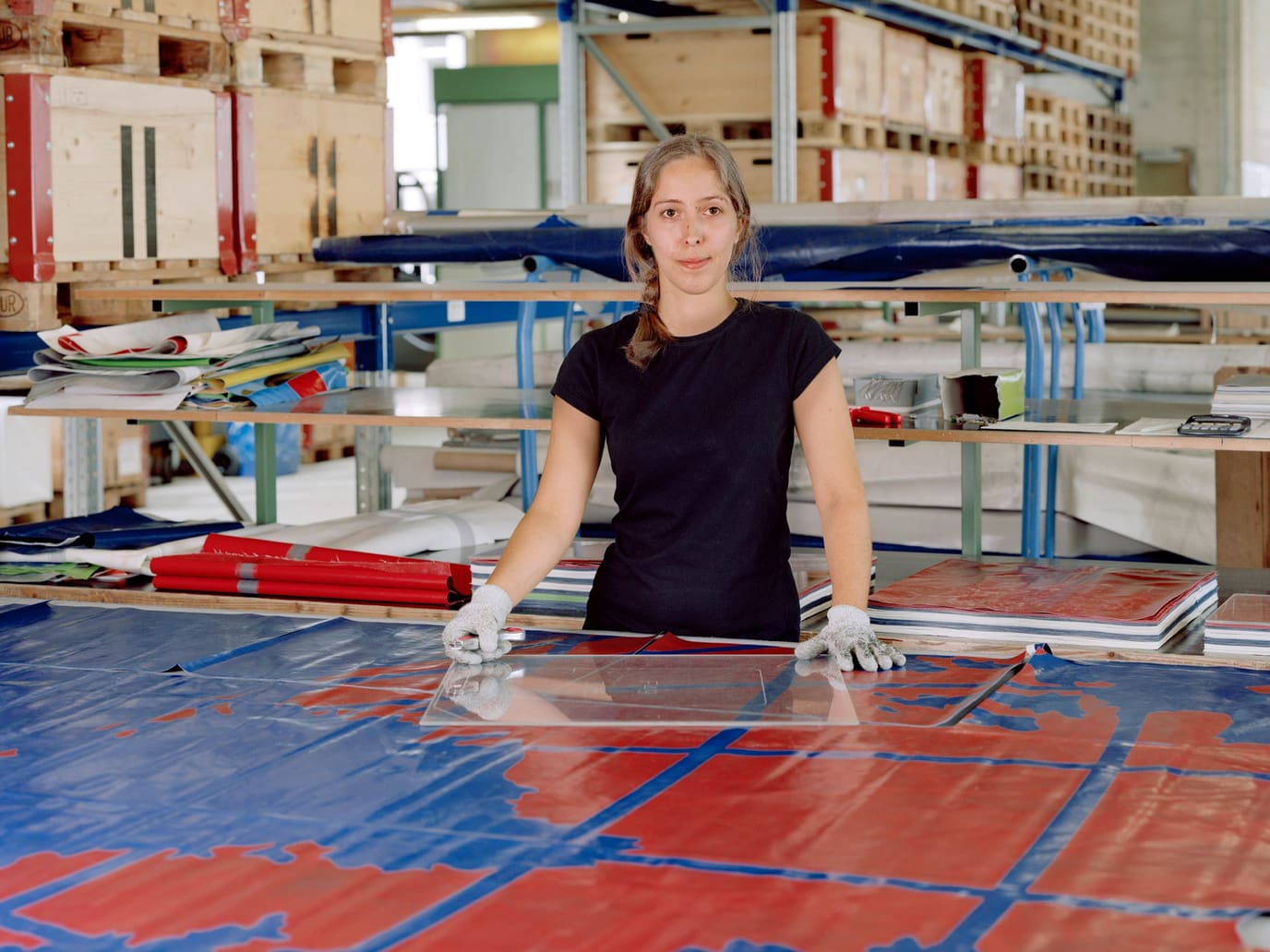

Creative, but tough: Sara and her co-designers fashion every single bag ...

... using templates and their cutters to carve the most beautiful and exquisite designs from the tarps.

After they’ve revealed the inner beauty of the tarps, and as soon as they are dry again ...

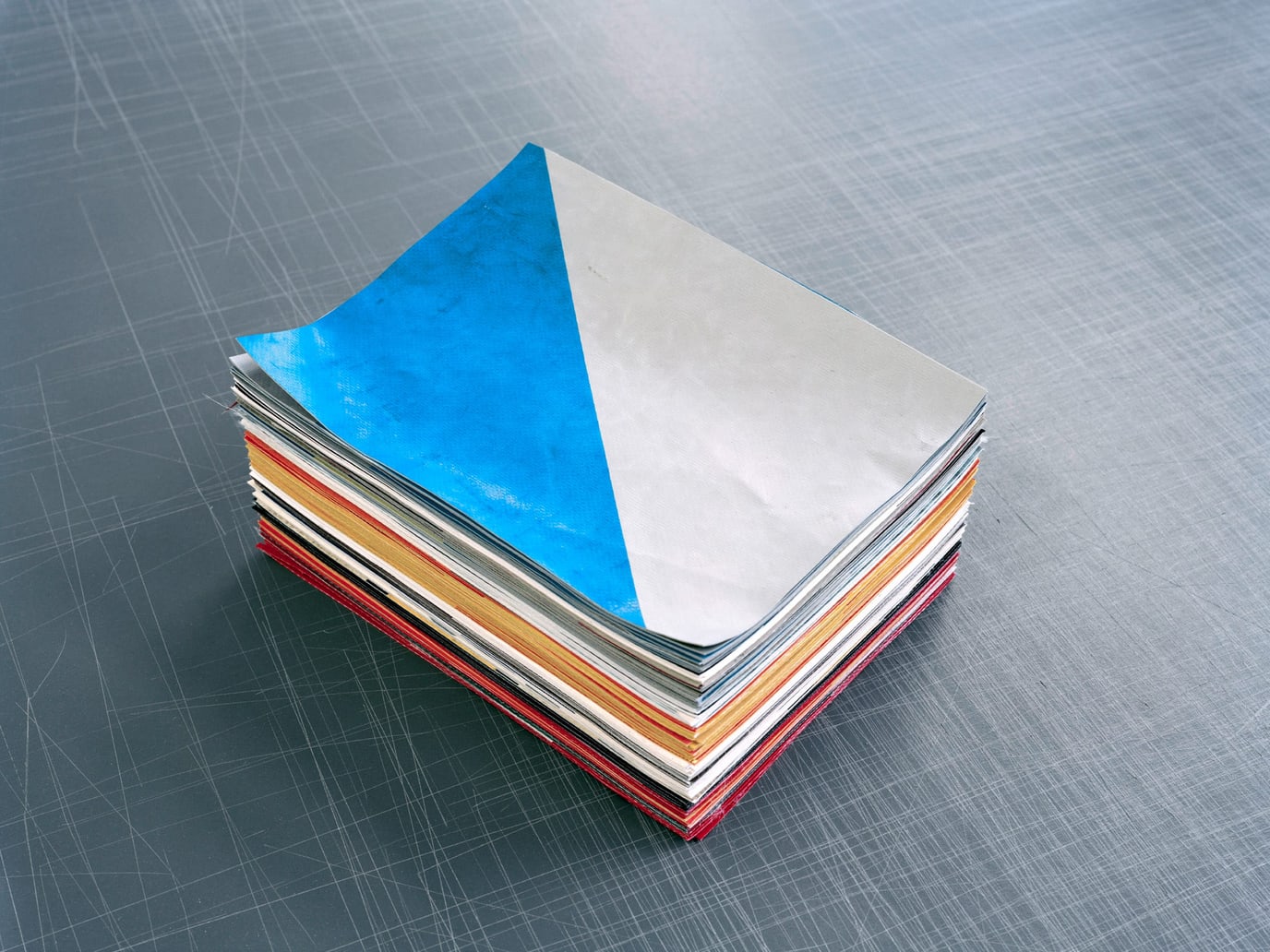

The tarp pieces are then stacked, numbered and sent to the sewing departments.

STEP 5: BAG COMPLETION

At the FREITAG factory, we only sew prototypes and test bags. Everything else – including your FREITAG bag – is entrusted to our experienced longtime partners, who are committed to complying with our Code of Conduct.

We entrust the sewing of your FREITAG bag to experienced partners in Portugal, Poland, the Czech Republic, Bulgaria, Tunisia and Switzerland who know how to stitch tarps that are often relatively thick.

As soon as the bags are back at Nœrd, we show off our Swiss side ...

... and check them to ensure that everything is in order, and finally select the products that will end up in a crate together according our secret FREITAG color scheme.

Unique products, which will be sold in the online shop, are put on a pedestal and photographed from all sides.

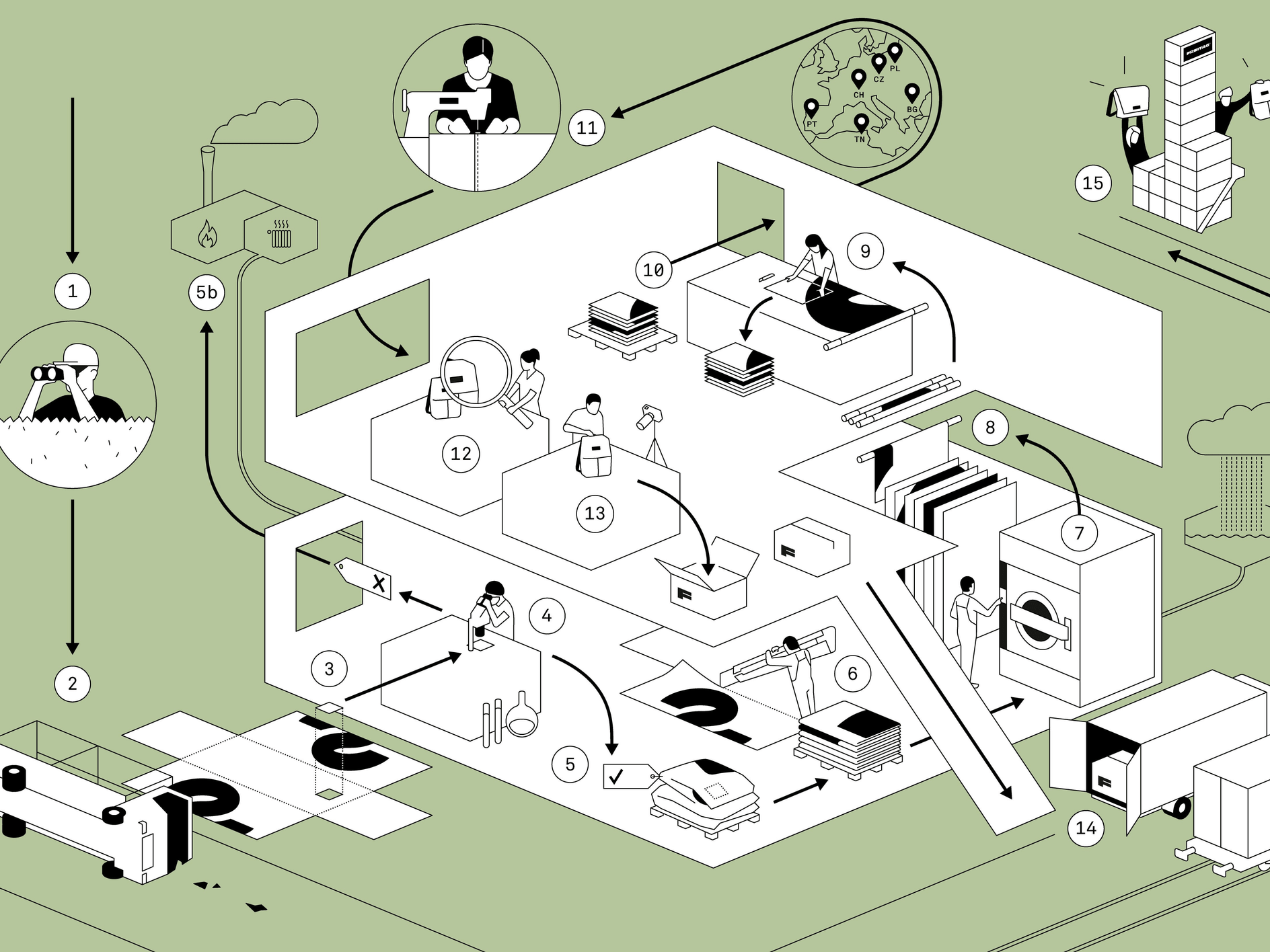

LESS TEXT - MORE STEPS

FREITAG’s one-of-a-kind bag production process for process engineers, flowchart fetishists, icon idolizers and all the other info junkies who prefer visual learning to reading:

Using recycled materials and short transport routes in our supply chain keeps our carbon footprint comparatively low. In 2021, it amounted to 4000 metric tons of CO2 equivalent, or about 600 flights around the world. Along our entire value chain, we are actively working to further reduce our direct and indirect greenhouse gas emissions. If you want to know more about other measures we’ve introduced over the past year and our future plans, you can find out all about them in the first FREITAG Impact Report.